The day-to-day emerging needs for PPE gear and medical devices amid the COVID-19 pandemic worldwide are making it difficult for personal protective equipment manufacturers to meet the demand spikes. Since we all are aware that the main cause for the spread of coronavirus is through droplets generated when an infected person coughs, sneezes, or speaks, wearing facemasks and face shields prove to be effective in controlling the spread of the virus. The increased demand and panic buying has led to the critical shortage of face masks and shields in the market. And therefore, the face mask and face shield manufacturers have come to the forefront to launch new techniques to meet the high demand for disposable face shields and masks.

As face masks and respirators have become difficult to find in the market, the face shield has quickly emerged as an alternative that is easy to manufacture and effective in preventing the spread of the virus. Different face shield manufacturers deploy different manufacturing processes that result in the availability of face shields in a variety of impressive designs and styles. This variety in designs is primarily due to the wide range of expertise, skills, and equipment available to manufacturers.

As one of the leading bulk PPE suppliers in the USA, we bring an exquisite collection of face masks and face shields designed by crafty personal protective equipment manufacturers of Asia and the USA. Amidst the global pandemic, we care for you, and therefore, we never compromise on the quality and the material of the essential medical-grade products. With a wide range of face shields available in the market, we have compiled some of the designs and styles of face shields that are produced by some of the best face shield manufacturers and high-profile companies.

How Do Face Shields Extend Life of Face Masks?

Face masks, when used correctly, should be changed every time a doctor or nurse treats a new patient. However, due to the acute shortage of face masks and respirators, many healthcare experts have been asked to wear one face mask throughout the day. That same mask could carry virus particles or pathogens on them and potentially spread COVID-19 within the healthcare setting and endangering healthcare professionals.

Face shields can address this issue by providing another device for protection covering the whole face. They add a layer of protection to the face masks while extending the life of face masks and respirators. Face shields protect the healthcare workers and their face masks from coming in direct contact with virus particles spread through coughing or sneezing.

Being one of the bulk PPE suppliers in the USA, we supply the best-quality face shields to help people and frontline COVID-19 warriors fight against the pandemic.

Different Types of Face Shields Amidst the COVID-19 Pandemic

1.Plastic and Elastic Strap

Unsurprisingly, the world’s highest-profile company Apple is producing face shields. The company now ships out one million face shields a week from factories in the USA and China. Each face shield consists of two pieces of plastic and a piece of elastic strap, both cut from large sheets.

Another reputed architecture firm, Foster + Partners, which coincidentally has close partnerships with Apple, is also manufacturing a similar, yet more complicated design. This design is quite elegant primarily for two reasons: First, as all parts are cut from large sheets, it takes less time to manufacture. Laser cutting and die-cutting are much faster than 3D printing. Second, the face shields can be flat-packed which optimizes their volume when shipping.

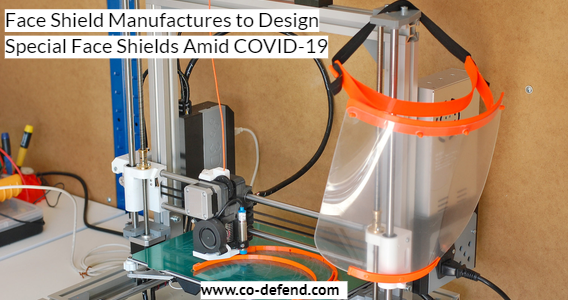

2. 3D-Printed Face Shields

Earlier, 3D printing was limited to small-scale rapid prototyping. But today, it has become a large-scale manufacturing technique used by various industry verticals. Unsurprisingly, many companies with 3D printing capabilities are using their printers for face shield production.

Carbon is one such company that produces a 3D-printed midsole for the Adidas 4D line of running shoes. The face shields designed by Carbon and Adidas involve a flexible, 3D-printed headband attached with a thin plastic visor. The headband has a hollow, yet strong cellular structure which reduces material use as well as print time.

While Carbon is using a stereolithography (SLA) process, there are other larger personal protective equipment manufacturers that are using every other major 3d printing technology to produce face shields.

3. Injection-molded Headbands

3D-printing offers a lot of flexibility as one machine is capable of producing a variety of products from various materials. However, injection-molding is significantly faster and cheaper at scale. Face shield parts are created by injecting molten plastic into a metal mold. The marginal cost of each part is economical. However, there is a considerable cost for the mold. So, injection molding is suitable for large-scale production.

Fictive, a well-known on-demand manufacturing company has already started using the technique to begin manufacturing shields quickly.

4. Foam headband

By now, you might have noticed a pattern here. Face shields are normally made from three unique parts, that is, a clear plastic visor, a headband, and an elastic strap around the head.

Foamband is the brainchild of members of a Makerspace at the University of Wisconsin—Madison. This elegant solution uses a thick piece of foam as the headband. The headband is attached to a strap and plastic visor. Ford has taken this design and is manufacturing face shields at scale.

Nike has come up with a similar solution using materials at their disposal, for example, they are using clear plastic normally used in Nike Airbags, and foam and cords with toggles from jackets.

5. Improvised Design

Some people are producing clips that can be used to attach a visor to a baseball cap. Tokukin Yoshioka, a Japanese designer created a similar, yet simpler solution using a pair of eyeglasses and a single plastic sheet. He cut out the shape of the visor and pierced two holes for either temple to go through.

6. Single Material

This type of face shield is made from a single material, that is, a piece of plastic cut from a large sheet. Design Friction Lab has invented a design, assembled from a few parts that are cut from the same sheet of plastic.

Face Shield Manufacturers Turn Adversity into an Opportunity to Show Creativity

Indeed, this global pandemic has revealed that humanity, when faced with the crisis, can apply its innovativeness and ingenuity towards creative solutions. Be it hobbyists at home printing out face shields manually, or large-scale face shield manufacturers flexing their whole supply chain to produce them by the millions, every producer has its own way to design face shields. The variety in the designs proves that there is not any standard guideline for producing face shields. Every contributor can leverage their unique set of materials, knowledge, and tools at their disposal.

Wrapping Up

So, these are some of the design and styles of face shields that exhibits the specialty and creativity of different face shield manufacturers and well-established companies. You can now easily identify the various types of face shields available in the market and choose the one that suits you best.

As one of America’s trusted bulk PPE suppliers in the USA, we make sure that we cater to the people with the best-quality PPE gear and medical devices to help them in the fight against COVID-19. If you need to place a bulk order for PPE apparel or medical device, we are just a click away.